High Current PCB Connector from Amphenol Delivers as much as 200 a Of Power

Warning: Undefined variable $PostID in /home2/comelews/wr1te.com/wp-content/themes/adWhiteBullet/single.php on line 66

Warning: Undefined variable $PostID in /home2/comelews/wr1te.com/wp-content/themes/adWhiteBullet/single.php on line 67

|

| Articles Category RSS Feed - Subscribe to the feed here |

|

|

SIDNEY, N.Y. , Sept. 3, 2015 /PRNewswire/ – Amphenol Industrial Products Group, a world chief in interconnect methods, now provides a compact, excessive current PCB power connector that allows energy supply of 35 A to 200 A. Amphenol’s SMT Radsert provides a flexible design that may accommodate any dimensional constraint and stack peak.prnewswire. Available in tape and reel packaging for high quantity functions, these new power connectors supply designers the flexibility to carry energy to a board from busbars suspended above or under the board and its elements. SMT Radsert connectors are supplied in each press-fit and solder variations. They are rated for functions starting from 35 A to 200 A. The connector’s RADSOK pin and socket technology provides excessive reliability and sturdiness whereas offering high current ratings, low mating force in addition to increased amperages inside smaller footprints. SMT Radserts not only function reliable operation, but also gives more surface house inside a circuit board design while eliminating threaded connection failures. If you have any thoughts regarding where and how to use High-speed PCB connector review, you can speak to us at our own website. They’re very best to be used in excessive-present, single-point connections. Delivery is 6 weeks ARO. READER SERVICE INQUIRIES: Please forward all reader service inquiries to John Griffiths at Amphenol Industrial Products Group, Amphenol Corporation, 40-60 Delaware Ave, Sidney, N.Y. Editor’s Note: Amphenol Industrial Products Group, headquartered in a 675,000 square foot facility in Sidney, N.Y. Products include ruggedized-for-industry cylindrical, fiber optic, rectangular, and industrialized variations of Amphenol’s MIL-DTL-5015 cylindrical, MIL-DTL-26482 miniature cylindrical and GT reverse bayonet cylindrical connectors. It employs greater than 1,400 people and is ISO9001, TS96949 and MIL-STD-790 certified.

SIDNEY, N.Y. , Sept. 3, 2015 /PRNewswire/ – Amphenol Industrial Products Group, a world chief in interconnect methods, now provides a compact, excessive current PCB power connector that allows energy supply of 35 A to 200 A. Amphenol’s SMT Radsert provides a flexible design that may accommodate any dimensional constraint and stack peak.prnewswire. Available in tape and reel packaging for high quantity functions, these new power connectors supply designers the flexibility to carry energy to a board from busbars suspended above or under the board and its elements. SMT Radsert connectors are supplied in each press-fit and solder variations. They are rated for functions starting from 35 A to 200 A. The connector’s RADSOK pin and socket technology provides excessive reliability and sturdiness whereas offering high current ratings, low mating force in addition to increased amperages inside smaller footprints. SMT Radserts not only function reliable operation, but also gives more surface house inside a circuit board design while eliminating threaded connection failures. If you have any thoughts regarding where and how to use High-speed PCB connector review, you can speak to us at our own website. They’re very best to be used in excessive-present, single-point connections. Delivery is 6 weeks ARO. READER SERVICE INQUIRIES: Please forward all reader service inquiries to John Griffiths at Amphenol Industrial Products Group, Amphenol Corporation, 40-60 Delaware Ave, Sidney, N.Y. Editor’s Note: Amphenol Industrial Products Group, headquartered in a 675,000 square foot facility in Sidney, N.Y. Products include ruggedized-for-industry cylindrical, fiber optic, rectangular, and industrialized variations of Amphenol’s MIL-DTL-5015 cylindrical, MIL-DTL-26482 miniature cylindrical and GT reverse bayonet cylindrical connectors. It employs greater than 1,400 people and is ISO9001, TS96949 and MIL-STD-790 certified.

The PCB pins can legitimately be referred to as the inspiration of every PCB design. Much like the way PCBs do, pins operate just like the interconnect system as well as numerous plug-in purposes. The circuit board design does indeed have a major quantity of performance thanks to hooks. Circuit board pins may be pushed in to circuit, swaged, and, for most circumstances, soldered it to Circuit board to be able to attach them to it. A mandatory conductive channel for the electrical circuit is provided by PCB pins. Because the mechanical interface, it provides an meeting module energy. What are the Common PCB connector types? How Can PCB Connector Be Tested? So as to connect two components and maybe a circuit board electrically, PCB header pins is ceaselessly employed. Although there are quite a few completely different kinds of PCB header pins, they’re usually male connectors arranged inside a row and spaced apart by a set distance and range.

Such components which can be difficult to mount on standard connectors or circuit boards are steadily mounted using the PCB pin socket. The PCB pin socket is often used on the Circuit board to pick out such options having single contact points. The ranges as well as dimensions of PCB pin sockets make it simpler for customers to pick out a number of of their choices primarily based on their needs. During current years, press-match pins have developed, making it less complicated for engineers and designers to use the press-fit and solderless connectors. The PCB pins remain easy to make the most of and produce the process of manufacturing much less pricey in addition to being extra accessible in contrast to the conventional strategies. The engineer will find it much simpler to debug a circuit in this situation. The components put in on the Circuit board are mechanically supported by PCB alignment as well as PCB information pins. Alternatively, PCB solder pins is among the most often utilized PCB pins when such connectors are connected to the circuit board prime.

Their typical uses are within the creation of circuit boards and prototypes. Jumper pins on PCBs are regularly utilized to provide a path of conduction over a bypass element of an electrical circuit that is open or closed. They are essential because the bypass connection must be made for the digital parts utilized in PCB board by the designer. The PCB terminal pins have been made to fulfill the expanding wants of the electronics sector. The PCB’s terminal pins supply separate, high-current connections. The designer can create multiple installation schemes to serve the designs due to the varied types and patterns of the PCB pins. Engineers now find it a lot easier to operate on prototypes or finished PCB designs because of PCB pin advances and enhancements. Many additional intricate patterns that may have seemed impossible to perform utilizing typical techniques have now been made viable thanks to those breakthroughs. How Does a PCB Connector Work?

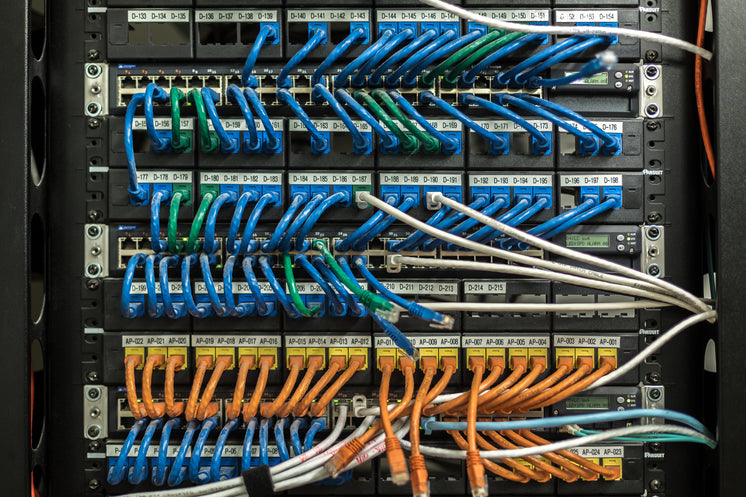

The PCB connector is often located on the circuit board and are often used in transferring energy or indicators from one Circuit board to a different, in addition to from another source inside the unit, from or to the PCB. For the reason that Circuit boards usually are not completely connected to one another and could be put together later throughout a process of production, PCB connector assembly connectors provide a simple solution to design. What are the Common PCB connector sorts? PCB board connections are utilized in a wide variety of gadgets. The design therefore must be applicable for the sort, measurement, as well as perform. This makes a variety of PCB connector options accessible. A cable is linked to a circuit board using this kind of PCB connection. The device facilitates connections within circuits. These are essentially a collection of pins having different spacings, additionally referred to as the pin headers. There could also be 0.197, 0.2, or 0.1 inches between each gap. Manufacturers can hyperlink PCBs without the need for a cable due to the board-to-board connectors.

The PCB connector is often located on the circuit board and are often used in transferring energy or indicators from one Circuit board to a different, in addition to from another source inside the unit, from or to the PCB. For the reason that Circuit boards usually are not completely connected to one another and could be put together later throughout a process of production, PCB connector assembly connectors provide a simple solution to design. What are the Common PCB connector sorts? PCB board connections are utilized in a wide variety of gadgets. The design therefore must be applicable for the sort, measurement, as well as perform. This makes a variety of PCB connector options accessible. A cable is linked to a circuit board using this kind of PCB connection. The device facilitates connections within circuits. These are essentially a collection of pins having different spacings, additionally referred to as the pin headers. There could also be 0.197, 0.2, or 0.1 inches between each gap. Manufacturers can hyperlink PCBs without the need for a cable due to the board-to-board connectors.

Find more articles written by

/home2/comelews/wr1te.com/wp-content/themes/adWhiteBullet/single.php on line 180